| ⦿ Easy to use with color touch panel |

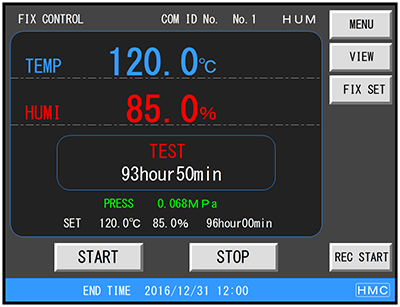

| MENU screen | MONITOR screen |

|

|

| Monitor, graph display, mode setting, program setting, test name entry, and other menus are displayed. | Specialized in visibility, the operation state and various figures are displayed in a large size. (Pressure indication is equipped as standard.) |

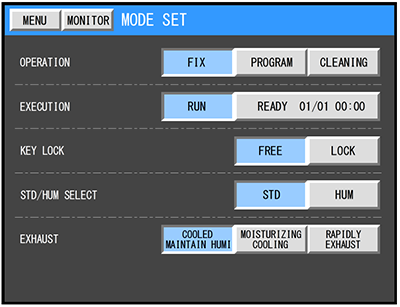

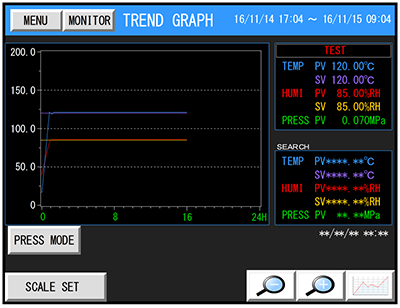

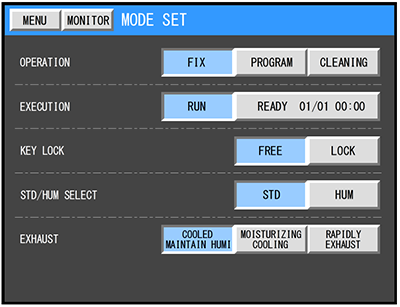

| TREND GRAPH screen | MODE SET screen |

|

|

| The set program pattern or progress state of a program can be checked on a graph. There is a scaling function that changes the temperature and time scale to make the program pattern easy to see. | Operation mode, execution mode, operation selection, STD / HUM, Exhaust mode can be set. Touching the key changes the screen to the detail setting screen of each item. |

| ALARM screen 1 | ALARM screen 2 |

|

|

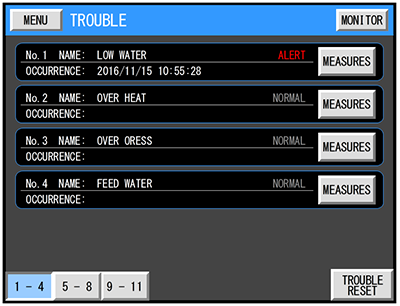

| [ TROUBLE MONITOR screen ] Various alarms are displayed individually. When an alarm is activated, it is displayed in red along with the alarm occurrence date and time. |

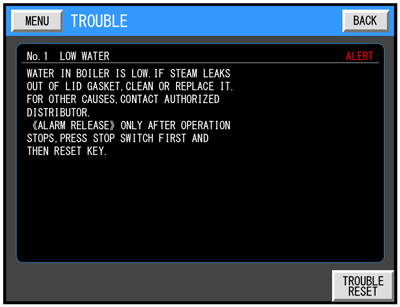

[ Alarm message screen (Troubleshooting) ] The causes and measures for generated alarms are displayed on the message. You can restore the state by operating according to the message. |

| ⦿ Two control methods |

|

|

| [ HUM / Unsaturation control ]

The unsaturation control mode prevents dew condensation and can set the humidity at any value between 65%RH and 100%RH. In addition, temperature gradients at temperature rise and fall can be set for both fixed value operation and programmed operation, and humidity control is also possible. This mode meets the test conditions defined in IEC 60068-2-66 and JIS C 60068-2-66. |

[ STD / Saturation control ]

This is a 100%RH saturation test mode, and humidity is maintained at 100%RH from a start. This mode is also called as a wet saturation test, and dew condensation occurs on the specimens. A test that corresponds to the conventional saturated type pressure cooker can be carried out. |

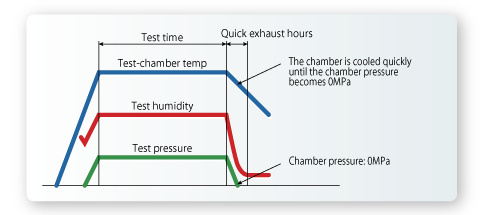

| ⦿ Three exhaust modes |

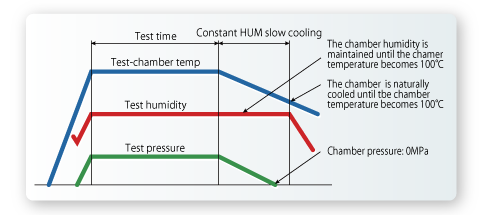

| 1.Slow cooling with humidity maintained mode

After completion of a test, the test chamber is cooled down slowly with humidity maintained until the chamber temperature becomes 100℃ and the chamber pressure drops to 0MPa. This mode can protect specimens from pressure stress and drying that are caused by rapid exhaust. The high accurate test that minimizes the influence on the specimens caused by taking them out on the way can be performed. |

|

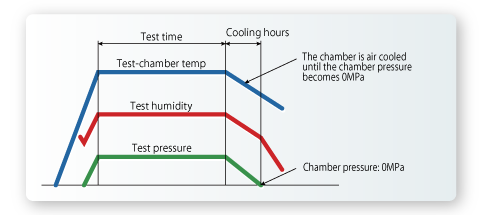

| 2.Cooling with moisture kept mode

After completion of a test, exhaust is not carried out until the chamber pressure reaches 0MPa, and air cooling with a fan minimizes pressure stress and drying. Cooling in a short time compared to the slow cooling with humidity maintained mode is possible. |

|

| 3.Quick exhaust mode

Immediately after completion of a test, the exhaust valve is opened to carry out exhaust and hot water drainage in a short time. The time from the end of a test to the removal of specimens is the shortest in all modes. This mode is suitable for specimens that are not affected by pressure stress. Data is compatible with the data of a saturated type pressure cooker. |

|

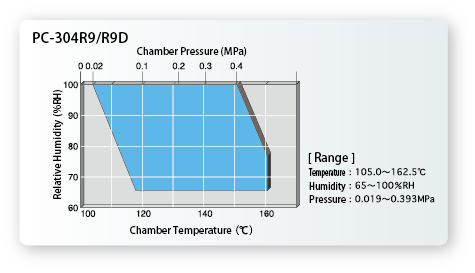

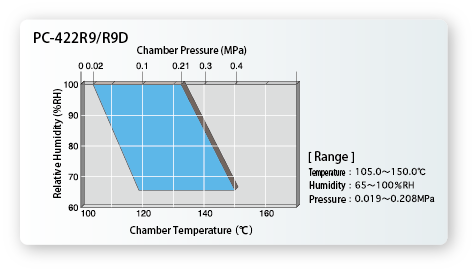

| ⦿ Temperature-humidity control range during testing process |

|

|

| ⦿ Specifications |

| Model | PC-422R9 | |

| Outside dimensions | W710 x D950 x H1620 mm | |

| Test chamber size | φ420 x D657 mm (84.4 L) | |

| Effective chamber size | φ340 x D475 mm (40 L) | |

| Weight (Approximately) | 280 kg | |

| Power supply | AC220V / 230V / 240V, 50Hz / 60Hz (Single phase) | |

| Required power supply facility | 3.0kW | |

| Heater capacity | Steam generator | 1.5kW |

| Test chamber | 1.3kW | |

| Temperature control method | PID control, SCR drive | |

| Test mode | HUM: Unsaturated test mode / STD: saturated test mode | |

| Operation mode | Fixed-value operation mode / Programmed operation mode (150 patterns, up to 1500 steps) | |

| Temperature | Working range | 105.0℃ – 133.3℃ (at 100%RH) |

| 105.0℃ – 140.0℃ (at 85%RH) | ||

| 118.0℃ – 150.0℃ (at 65%RH) | ||

| Control accuracy | ±0.5℃ | |

| Distribution accuracy | ±0.5℃ (at 100%RH) | |

| ±1.0℃ (at 85%RH) | ||

| Humidity | Working range | 65%RH – 100%RH |

| Control accuracy | ±3%RH (at 85%RH) | |

| Pressure | Working range | 0.019MPa – 0.208MPa |

| Pressure vessel category | Small sized pressure vessel | |

| Time | Working range | Continuous operation up to 500 hours is possible. |

| Setting range | 1 min – 999 h 59 min | |

| Temporary power failure compensation | Approximately 4 seconds | |

| Temperature rise time | About 70 min (time to 120℃ 85%RH from room temperature) | |

| Exhaust mode | EXHT MODE selector switch

MODE1: Slow cooling with humidity maintained mode MODE2: Cooling with moisture kept mode MODE3: Rapid exhaust mode |

|

| Voltage application terminal | 20 (Applied voltage:125V, within 30W in total) ※Number of terminals can be increased as option. | |

| Time signal terminal | Number of time signal terminals: 4 | |

| Chamber material | Stainless steel (SUS316L, electrolytic polishing treatment) | |

| Water supply method | A water supply tank is built in, and initial water supply to the steam generator is automatically carried out. | |

| Door open-close method | Drawer door structure, Electric clamp method | |

| Power connection | Ring terminal | |

| Safety devices and alarm functions | Pressure safety valve, Over-pressure prevention device, Overheat prevention device, Low water cut off device,

Water supply abnormality detection device, Over-current and earth leakage breaker, Circuit breaker for heater,Fuse, Thermal fuse, Door safety system (Door lock check mechanism during operation, Door open / close check mechanism), Protection for settings, Hot water drainage treatment system, Self-diagnosis function of sequence controller, Negative pressure prevention system |

|

| Supplied accessories | Lid gasket x 2, Drainage hose x 2, Water supply / drainage hose x 1, Auxiliary water supply tank x 1,

Power supply switch key x 2 (4 for R9D), Power supply cord x 1 (2 for R9D), Operation Manual x 1 |

|

※Air HAST mode (testing under residual air and pressure) can be provided as an optional device.

※The above outside dimensions do not include the size of protrusions.

※The performance values were obtained when ambient temperature was normal and the test chamber was empty.

※Specifications and appearance are subject to change without notice due to continuous product improvement.